Smart safety officers already know that a UniMac industrial washer is as tough as a fire truck—and built to last even longer.

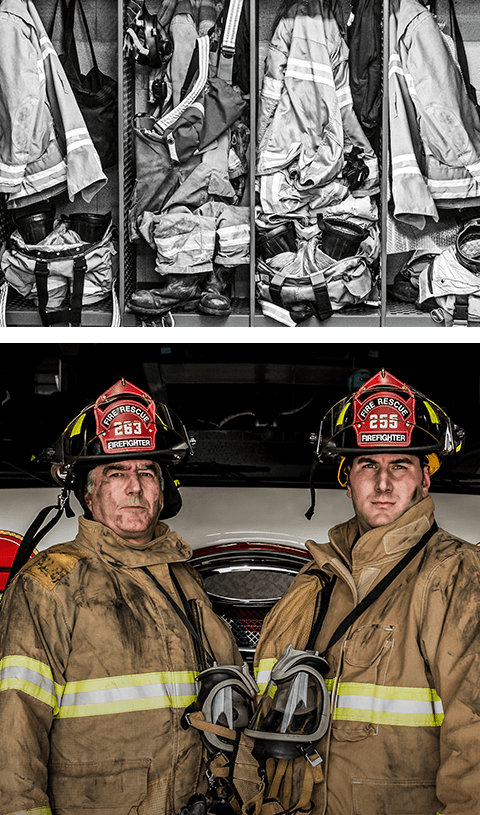

Protecting your department means addressing safety not just during fires — but before and after.

Knowledge is power

In eras past, it was considered a badge of honor to wear “seasoned” equipment. Today, however, we understand the risks firefighters face due to harmful carcinogens.

- Plastics and synthetics are more common in today’s households, making residential fires more dangerous due to an increase in toxic and carcinogenic combustion products.

- Unsafe contaminants and dangerous smoke particulates easily penetrate turnout gear and are promptly absorbed within the fabrics of PPE

- We now know that for every five-degree increase in skin-temperature, absorption increases 400%.

- With all this in mind, it’s no surprise that in 2016 cancer was responsible for 70% of all line-of-duty deaths among career firefighters.

UniMac is always up to date—so you are too

Smart safety officers already know that a UniMac industrial washer is as tough as a fire truck—and built to last even longer. But these days, the job is as much about brains as it is brawn. That’s why, when you invest in UniMac, we offer more than just a “machine”; we offer an entire system—including programmable controls and FireLinc reporting technology—that will be prepared to answer the bell for decades. So, you can rest assured that you’re following today’s regulations—but more important, that you’ll be ready for future standards and best practices, no matter how they evolve.

Important best practices

The basics*:

- PPE requires customized wash programs, with different cycles used for outer shells and inner liners. These items each have unique qualities and specialized care requirements, and should not be washed together.

- Begin the exposure-reduction and cleaning processes at the fire scene. For example, if possible, bag contaminated gear at the fire scene and isolate it from the passenger area of vehicles.

- Advanced cleaning is best accomplished with a minimum 30-lb-capacity washer extractor with fully programmable controls—including water-temperature control and a 100 g-force extraction setting. This meets today’s requirements while allowing the flexibility to ensure adherence to future requirements.

- All closures (snaps, Velcro, zippers, etc.) should be closed prior to washing.

- Inner liners should be washed with the moisture barrier on the inside. In most cases, this means turning the garment inside-out.

- There are special cycles and/or processes for specific contaminants (e.g., body fluids), and they must be followed.

- Always ensure the drying process is complete before PPE is put back in service. If done properly, machine drying is an option for speeding the drying process.

- Assure best practices are followed and recorded with each cleaning. Meticulous record-keeping paired with best-in-class cleaning protects everyone.

- *Please note: The points above should serve only as a quick-reference guide. Departments should receive training on the PPE-cleaning process directly from verified ISPs and/or element manufacturers. Additionally, in line with the increased understanding of the dangers firefighters face, the forthcoming iteration of NFPA regulations will become exponentially more stringent—and will recommend washing PPE after every fire.

FireLinc™

You have bigger fires to put out than maintaining wash records

Dangerous hydrocarbons left on gear pose a number of problems—including a doubled risk of many cancers. With this in mind, forthcoming NFPA standards recommend protecting your company by washing PPE after every fire. UniMac machines—equipped with TotalVue™ and the cloud-based FireLinc™ application—let safety officers easily maintain a full gear-washing history for each member of their team.

Sync with your inventory-tracking system

Sort by equipment ID, location and who completed wash

See what machine—and which cycle—was used

Export wash history to spreadsheet for easy auditing

Furthermore, as industry experts in fabrics, PPE manufacturers, chemists, labs and certified ISP’s continue to refine PPE-cleaning best practices, rest assured that UniMac and FireLinc will stay right in step, bringing that expertise to your stations and assuring it’s factored into every wash

Cleaner gear. Spotless data. Zero hassle.

Keep your company audit-ready without manual logs. The FireLinc application maintains a user-friendly interface to keep information entry—and access—easier than ever.

- Log in to the application.

- Select the location and machine where gear will be washed.

- Choose the appropriate wash cycle for your gear.

- Enter item number by scanning either bar code or RFID, or manually enter ID.

Scanned items uploaded to the TotalVue website can be searched by equipment ID, location, wash date or wash operator, giving you easy access to detailed cycle information. With time and date stamps to record the number of washes and how gear was washed, you can ensure best cleaning practices are met every step of the way for every item in your PPE inventory. The intuitive FireLinc software makes recording and organizing all of your wash data effortless.

Important Safety Tips

Many firefighters put their own well-being on the back burner while attending to the safety and security of their community. While this should never go unnoticed, it’s important to remember that in 2016 cancer was responsible for 70% of all line-of-duty deaths among career firefighters. With this in mind, there are thoughtful ways firefighters can protect themselves while maintaining the safety of their surroundings.

- Always wear SCBA in active and post-fire environments.

- After an active scene has been cleared, execute a gross field decon and use wet towels to remove as much soot as possible. Afterwards, isolate and contain your equipment.

- Once back at the station, change clothes and wash them immediately.

- Always shower after a fire.

- Attend annual medical physical exams and encourage your brothers to do the same.

- Avoid storing PPE equipment in your home, your vehicle or in the fire station living quarters.

- In accordance with forthcoming NFPA standards, PPE should be washed after every fire.

- In addition to observing proper wash frequency, PPE should be washed in NFPA 1851-compliant laundry equipment at the proper extraction and temperature settings using the proper chemicals. Thorough wash records should be maintained to ensure best practices are followed for every piece of PPE in your inventory.

The Power of Prevention Starts with Unimac

Download an eBook specifically designed with The Brotherhood in mind.

Get a Grant

THE ASSISTANCE TO FIREFIGHTERS GRANT (AFG): The AFG’s primary goal is to uphold the health and confidence of our nation’s firefighters by assisting departments across the U.S. in their courageous efforts to maintain safe and secure communities. Through this grant, departments can receive a generous fund to help acquire essential, top-of-the-line, NFPA-compliant washer extractors and PPE drying cabinets. Cleaning PPE is a life–safety issue and should be noted as such in grant writing.

Useful Links

- Your UniMac distributor can help customize an on-premises laundry solution for your PPE-cleaning and record-keeping needs.

- National Fire Protection Association

- NFPA 1851: Standard on Selection, Care, and Maintenance of Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting

- Firefighter Cancer Support Network

- U.S. Fire Administration