Lean on technology to erase lint and issues it creates

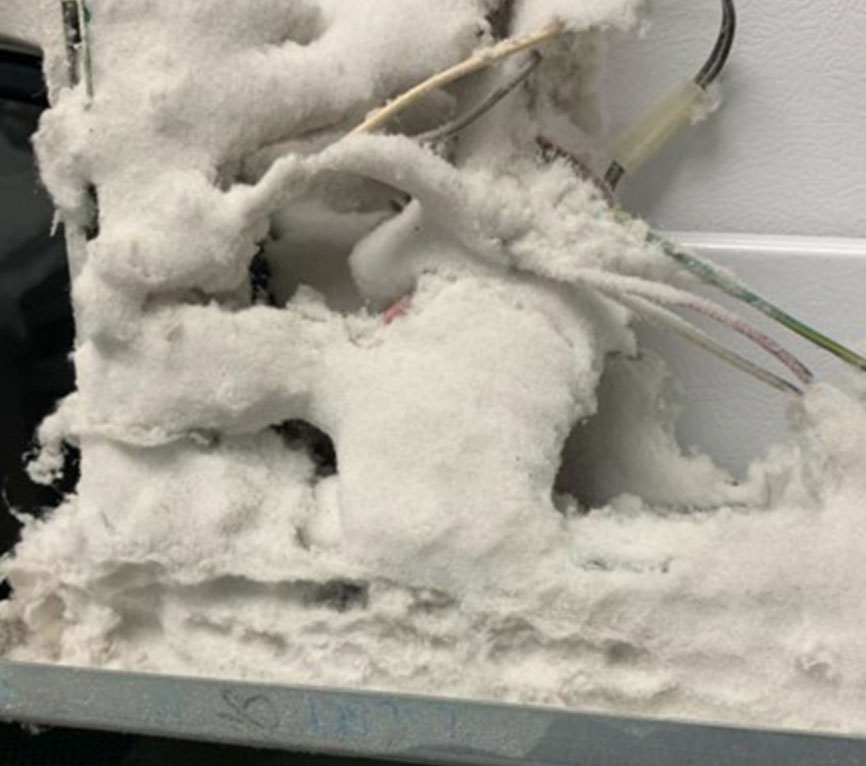

Ever stop to think about why, despite staff’s best efforts, the laundry room is in constant need of cleaning? It’s that little thing known as lint. For as seemingly small as it appears, lint can play costly havoc on HVAC systems, electronics, and many other areas.

There are two ways to tackle lint and the issues it creates, both technologies offered by UniMac.

Stop creating more lint than you should. All that lint that you are cleaning up is coming from somewhere – the linens your laundry is processing. The recipe is simple – the longer you dry linens, the more lint that is created. So, continuing to dry loads after they are dry contributes to making more lint, and, as a result, leading to linens wearing out early. Over-drying also wastes utilities and labor.

With OPTidry. You can preset the preferred dryness level for linens and the machine does the rest, drying to that level and then beginning the cooldown process. Don’t forget that “bone dry” isn’t the way to go; a bit of moisture is ok for linens headed to the shelf.

Collect more lint than you send out into the environment. For years, lint screens were the only answer to collecting lint, only pulling roughly 70 percent of dryer-generated lint. UniMac’s new ProCapture system utilizes cyclone technology to collect up to 98 percent of dryer-generated lint. More lint captured means less issues for your property as well as less staff time devoted to cleaning.

Though lint has always been an annoying byproduct of a laundry operation, managers can leverage new technology to virtually eliminate it from the equation.