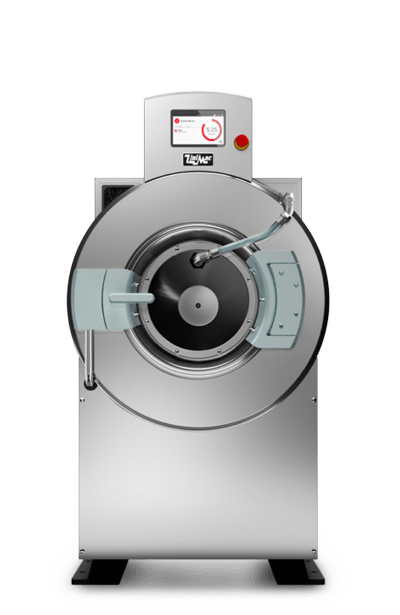

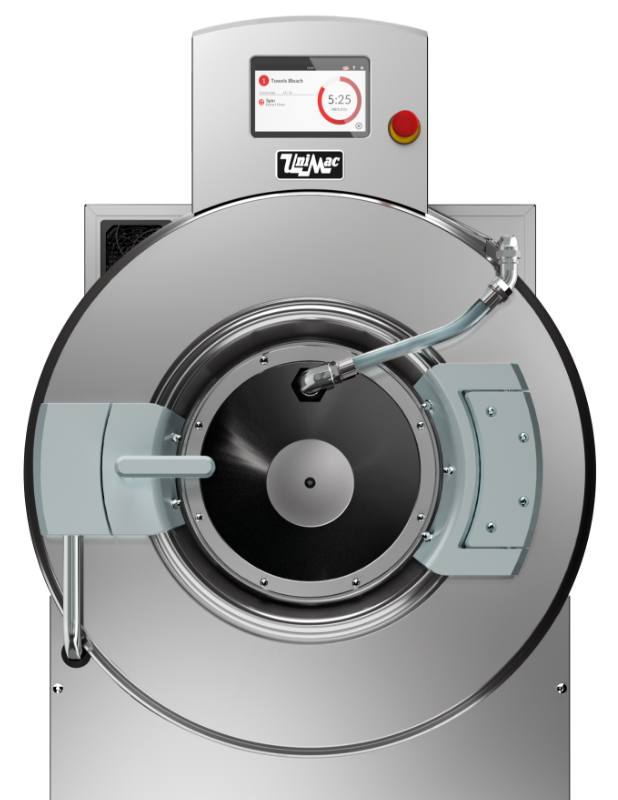

Industrial Laundry Equipment and

On-Premises Laundry Machines

To achieve maximum throughput, you need nonstop performance and equipment you can trust to consistently deliver the best clean. UniMac’s® full line of hard-working, industrial washer extractors, tumble dryers, light commercial laundry equipment and finishing ironers set the standard for top-quality clean. Designed and constructed with innovative technology only UniMac can deliver, investing in our equipment ensures you’re getting long-lasting machines, cutting-edge technology and unmatched efficiency. Plus, UniMac gives you the lowest total cost of ownership in the commercial laundry industry.